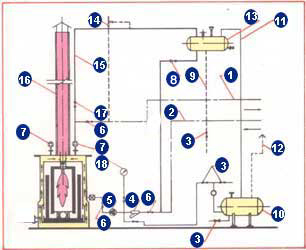

| I Pass : | First pass of the flue gas is

downward inside sprially wound coil through which thermic oil circulates. Expose to maximum hearting area to rediant heat. |

|

| II Pass : | Upward in between the two spirally

wound coil. Unique bell bottom design reduces stack loss. | |

| III Pass : | Downward between outside coil &

inner shell. Uniue bell bottom design reduces stack loss. | |

| Insulation : | Combution air is forced between the two shell & aluminium radiator which acts as insulation for outer shell & perheats the air for better combution efficiency. | |

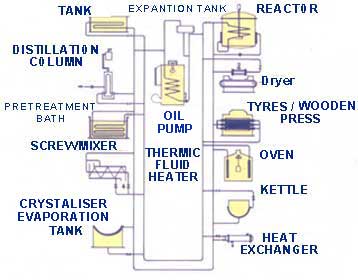

| Burner & Controls : | Fully automatic, downward firing,

pressure jet, ON-OFF modulation or High / Low modulation. Burner will have all safeties like flame failure device (Photocell) high temperature cut off. low flow safety, high pressure cut off. In case of abnormal condition unit will go to lockout, by audio-visual alaram. The modulation is achived by providing on-off temperature controller which will start & stop the burner according to heat load & reduces fuel consumption in proportion to heat load in plant giving best fuel efficiency for plant operation. |

|